Super Video 2.1XL

Super Video 2.1XL

From the pen of AC's "occasional columnist" Ben Poehland comes the final, gutwrenching word on cleaning up video problems in all the XL-series computers, as The Alchemist brutally reveals the scandalous acts of the Sunnyvale Butchers. Clean video at last for the 600XL, 800XL and the 1200XL owners!

Perspectives On 1200XL video

Despite the abundance of extra parts in the 1200XL video section, it turns out the basic design of the 1200XL video amplifiers isn't much different than the ones in the 800XL and 600XL. In all three machines color is handled by a group of three transistors, while the baseband monochrome/composite output is a separate single-transistor circuit. All these transistors are 2N3904 types. The table below summarizes the schematic designations of these transistors and briefly describes their functions:

| Function | 600XL | 800XL | 1200XL |

| 1st color amp | Q7 | Q2 | Q19 |

| 2nd color amp | Q8 | Q4 | Q8 |

| Color output | Q9 | Q5 | Q7 |

| Mono/CV output | Q6 | Q3 | Q11 |

Atari's most serious design and manufacturing flaws occurred in the baseband mono circuit, which screwed up both mono and color.

What sets the 1200XL apart from the other XL machines is an extra three-transistor circuit (Q16-Q17-Q18) whose input connects to the color sync signal at GTIA pin 25. The output is emitter-coupled to the color amp circuit via a diode (CR19) to Q19. It took me a while to dope out what this was for, but once I caught on my imagination was gripped in a spell of astonished wonder. This extra little circuit boosts color saturation. And The Alchemist is here to tell you its effect amounts to video magic. If Atari had included this extra 25-cents' worth of parts in all its 8-bit machines, and hadn't squandered it by butchering the rest of the video circuitry, the Atari 8-bit could have blown away the competition hands-down. Especially for color graphics and games!

Curing the video defects in the 1200XL was no easy task: the gremlins were well-entrenched with multiple lines of defense, and they fought The Alchemist tooth and nail every inch of the way. But, as General Grant discovered in the American Civil War, the secret of victory lay in lessons learned from the battles fought. That secret is to achieve a balance between three conflicting elements of the color output, which are: 1.) color saturation; 2.) color shadows; and 3.) sharpness (signal strength and bandwidth). The main rule of the game is: "Anything you do to improve one of these elements will necessarily degrade performance of at least one, and probably both, of the other two." Insofar as the monochrome amplifier plays a key role in achieving the best color display, improving the color display automatically results in optimized monochrome performance.

My philosophy was to tolerate a certain amount of color shadows while maximizing sharpness and saturation. This approach provides maximum benefit for both mono and color users. Color shadows don't affect the monochrome display at all, while the optimized signal provides the best possible screen sharpness for text. On color displays, the eye tends to be more forgiving of object shadows if the picture is sharp and clear arid full of brilliant color. Object shadows in the color display seem to me a video artifact that varies according to the particular combination of colors on the screen, being absent with some combinations and more noticeable with others. The S-V 2.1 upgraded 1200XL still exhibits some color shadow artifacting, but I'm gambling most people won't notice it while they're playing a fast-moving videogame on a crisp, vividly colored screen. In short, you game freaks will have a field day playing color games on a 1200XL upgraded to S-V 2.1XL using a luma-chroma interface.

S-V 2.1 For The 1200XL

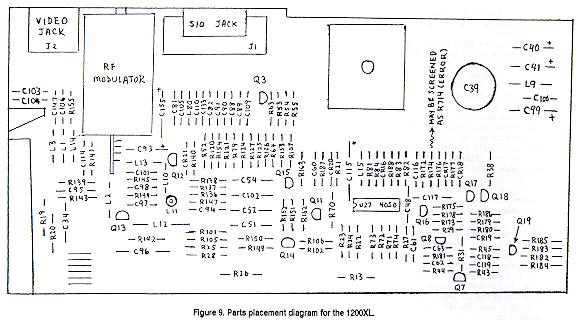

OK, let's do it. Refer to the board layout diagram in Fig. 9 for the following steps.

Step 1. Cut out the following components from the motherboard:

C60 CR20 C62 (1) R25 C101 (1) R28 (1) Might not be present in some computers.

Step 2. Carefully de-solder capacitors C103 and C104. One of them will be reused. You don't have to clear the vacated board holes of solder.

Step 3. De-solder the following components from the board and clear the vacated board holes of solder:

C63 L15 R145 (1) C99 R21 R181 C115 R44 R187 (1) Might not be present in some computers.

Step 4. Install the following components at the indicated locations:

| Part | Value | Code/Mark | Location |

| Capacitor, glass ceramic | .001uf (1) | - - - | C63 |

| Capacitor, electrolytic | 220uF/16V (2) | - - - | C99 |

| Jumper wire | - 0 - | - - - | C115 |

| Resistor | 100 ohms | brn-blk-brn-gld | L15 |

| Resistor | 1.5K | brn-grn-red-gld | R21 |

| Resistor (3) | 75 ohms (3) | [brn-grn-brn-gld]x2 | R44 |

| Resistor | 10K | brn-blk-orn-gld | R145 |

| Jumper wire | - 0 - | - - - | R181 |

| Resistor | 2.7K | red-vio-red-gld | R187 |

Notes:

(1)Use one of the caps removed in Step 2 above.Step 5. Select a 120-ohm resistor (brn-red-brn-gld). Rend the leads and cut to an appropriate length, and solder this resistor in parallel on top of R23 on the component side of the board.

Step 6. Prepare a synthesized 75-ohm resistor by twisting two 150-ohm resistors (brn-grn-brn-gld) together in parallel and soldering the leads together. On the component side of the board, solder one end of this part to the top of R22 and the other end to the bottom of C48.

Step 7. Select a 120-ohm resistor (brn-red-brn-gld). Trim one lead to a length of about 1/2". On the component side of the board, solder the short lead of the 120-ohm resistor to the top of R24, and allow the 120-ohm resistor to stand vertically. Now, carefully de-solder the bottom end of R24 and clear the vacated hole of solder. Stand up R24 vertically alongside the 120-ohm resistor, and solder the free ends of the two resistors together. You should have at least 1/2" of lead length remaining at the free end. Form this extra length into a small loop about 3mm in diameter and trim off any excess.

Step 8. Cut two lengths of stranded wire 10" and strip 1/4" of insulation from both ends of each. Select a panel-mount SPST switch and solder one end of each wire to each lug. Twist these wires lightly through their whole length. Solder one end of one wire to the loop at the top of R24 you made in Step 7 above. Solder the other wire to the hole in the circuit board vacated by the bottom end of R24.

Step 9. Select a 330-ohm resistor (orn-orn-brn-gld). Bend and trim the leads appropriately, then solder this part in parallel on top of R45 on the component side of the board.

Step 10. Select a 100-ohm resistor (brn-blk-brn-gld). Place insulation (removed from wire) on both leads, leaving only 1/4" bare lead exposed. Now cut a length of insulated wire 10" long and strip 1/4" insulation from both ends. Solder one end of this wire to one lead of the resistor and insulate the joint with heatshrink tubing (NOT tape!). Now turn the 1200XL motherboard over and examine the foil side. What you want to look for are "channels" created by rows of resistors on the component side: we'll use these channels to route the chroma signal wire to the output jack. There are four of them; it will help to mark their location with a pencil. The first "channel" begins with R43 and ends with R186. The second begins with CR18 and ends with R153, the third at R107 and ends with CR21, and the fourth at R155 to end at C147.

Now locate R45 on the foil side of the board directly in front of Q19. On the foil side, solder the resistor end of the resistor-wire assembly to the end of R45 that's furthermost away from Q19. Bend and shape the resistor leads and wire so the resistor body lies in the middle of "channel 1", makes a right-angle bend to run down the middle of "channel 2" and a 45-degree bend to run down the middle of "channel 3", followed by a final 45-degree bend to run down the middle of "channel 4". This will bring the wire out close to the jack. Route the end of the wire through the break in the ground foil plane and solder the bare end to pin 5 of the output jack. This pin is easily located because it's the only one without a foil trace connected. Place three or four tiny dabs of hot-melt or silicone adhesive along the path of the wire to hold it in place on the underside of the board.

Step 11. Drill a hole in the rear panel of the bottom case directly above the channel selector switch, using a bit of appropriate size to match the mounting stem of your switch. Mount the CV Disable switch here after routing the wires out through the crack between the RF shield and the modulator box. This completes the modification.

[NOTE: Check out the 1200XL ClearPic circuit.]

1200XL Checkout and Wrap-up

Boot up the bare 1200XL motherboard (preferably with a cartridge installed) with a monitor attached as described for the 800XL and 600XL upgrades. Observe the effect of the CV Disable switch, most visible on a monochrome monitor. (The effect of the switch is usually not observable on color monitors.)

If you're using a color display with a CV or luma-chroma interface, you'll notice how sharp and brilliant the colors now are. If you de-solder one end of CR19 and lift it from the board, you'll have a color display that's identical to the color displays generated by the other S-V 2.1-upgraded XLs: sharp and clear, but with less vivid colors. Removing CR19 disconnects the saturation boost circuit; I think it looks better with CR19 left connected. Perhaps some enterprising hardware entrepreneur out there will make up a little circuit board kit for retrofitting Atari's saturation boost circuit to the other XLs; the electronic parts cost less than 50 cents.

Copyright © 1993

Atari Classics

1161 Bay St.

Alameda, CA 94501