A Bird's Nest

Falcon recasing

by Lyndon Amsdon

When the

Falcon was released it looked pretty much

like an ST from 1985, surely this was not

a good strategy by Atari, or did it think

this would make it instantly recognisable?

Who knows, but what I do know is that the

old case is far too limiting for such a

powerful machine. The Falcon was sold with

very slow 2.5" drives and very little

space for expansion, this was all powered

off a PSU that was crammed into the case

which causes quite a lot of heat to build

up.

These are

just some of the better reasons to put your

precious Falcon in a tower case with that

fast 3.5" IDE drive that had to be

pulled out of your PC because Windows XP

wouldn't fit on it. You'll get a lot better

cooling, which, combined with a better PSU

will help make the machine more stable.

The CT60 (a super 68060 booster) also requires

the ATX style power supply that is common

in all modern tower cases because it needs

3.3V which the Falcon PSU doesn't supply.

The main

thing you need for this project is patience

and preparation. Start off by stripping

the computer right down to the motherboard,

removing any internal drives and the PSU.

Next, get a piece of card the same size

as the motherboard and place the motherboard

on top of it. Draw around it with a pen

and mark out roughly the places for the

ports and any headers on the board (like

the IDE). Also familiarise yourself with

the board and check for loose wires on any

hardware upgrades while you're at it. Give

it a gentle dust down as well as the Atari

ST style cases tend to collect dust.

Take the

piece of card and pop into your local computer

shop to see it it'll fit in a PC full tower.

The tower case needs to be at least 50cm

high. You may get some funny looks so just

say your motherboard is larger than normal

because it's so good!

The ST and

Falcon motherboards are a lot longer than

PC ones so there is some metal work involved.

The majority of full tower cases are split

in two sections, one at the top for the

drives and the lower section for the motherboard

and cards. There is a metal strut separating

these two sections and a piece of this has

to be cut so the board can get in.

|

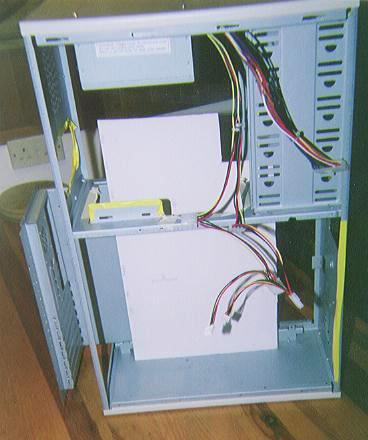

Tower case with

side off. Notice the two struts

that run from front to back,

seperating the two sections. |

When you

feel the case is fine then buy it and when

you get home remove everything off it including

PSU, drive carriers and if you can, the

front panel. Try fitting your card template

in and see what needs to be cut. Be extremely

careful when you do cut as the metal is

very sharp and in my second tower job I

covered the sharp edges with insulating

tape as I sliced the top of my knuckle off

on the STE tower, ouch.

Tools I used

were a junior hacksaw (with a sharp new

blade, it does help!) and a Dremel fitted

with a circular cutting wheel attachment.

My Dremel was too weak to actually cut the

tough steel so I used it to score and then

I used some pliers to bend it back and forth

until it snapped off. File the rough edges

smooth and make sure you clean out any metal

fragments, you don't want these anywhere

near your sensitive motherboard.

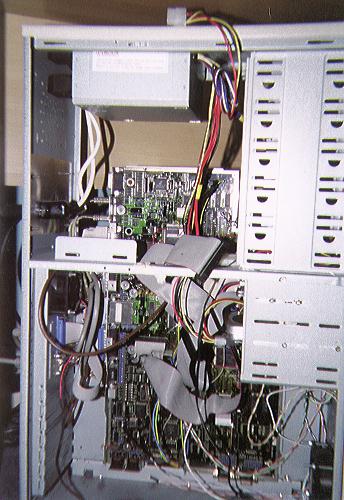

|

This shows the

piece of card in place. As you

can see the case was stripped

right back and sharp edges covered

with insulating tape. |

Now you'll

have to move the tower's PSU as the chances

are it will hit the motherboard when it

is in place. I mounted it at the top of

the case. The power supply had some screws

on the top to keep its enclosure together.

I removed these and bought some slightly

longer ones so I could drill holes in the

top of the tower case and screw through

holding the power supply up there.

|

The PSU had to

be moved to make way for the

large Falcon board. |

When you're

happy try fitting the card template in place

and see if any adjustments are needed. When

it fits fine bring in the Falcon motherboard

and see if this fits. Leave the metal shielding

on the back of the motherboard but remove

the top shielding for easy access to the

components. Position the motherboard remembering

that you'll probably have to sacrifice a

couple of 5.25" drive bays. Remember

the connectors at the bottom (cartridge,

MIDI...) so leave space if you need to use

them. On my Falcon I didn't want to use

these so I managed to get the gap from the

bottom of the case to the bottom of the

motherboard down to only a few centimetres.

You can get right-angled plugs to fit the

MIDI ports from Maplin so you don't have

to leave a huge gap, but if you use the

cartridge port for dongles and other add-ons

then you may need up to 10cm. Take into

consideration where the back ports will

be lined up against the tower's back panel,

leave roughly 5cm here as well.

Now use marker

pen to stencil the motherboard's mounting

holes onto the tower case, where you'll

drill holes. Please remove the board before

you start drilling these! Use 6-10mm board

spacers then use some small bolts (about

12-15mm long) to hold the motherboard in

place, remembering to use fibre washers

on the motherboard side. Don't tighten them

all the way up as there is still a fair

way to go. You'll need to remove the board

again to work on the electronics.

You'll need

to make or find leads to attach the ports

to the back of the tower case. I recommend

Maplin and Farnell. Maplin even stock those

rather odd 13-pin and 14-pin DIN sockets!

You'll also

need to extend the floppy ribbon cable.

The motherboard doesn't have a header that

simply unplugs, so you have to undo the

latches either side of this and carefully

pull the ribbon cable out. Now use a PC

floppy cable and snip off the connector

that connects to the PC motherboard. Place

the end of the ribbon cable over the Falcon

motherboard's connector so the red stripe

is towards the back of the motherboard and

each wire is in its groove. Use the end

of a match stick (not the ignitable end)

to push down the individual wires one by

one. After you think the wires are down,

place the connector's top on and press quite

firmly. If it doesn't latch on then you'll

need to press the wires down a bit more

with the matchstick.

If you have

a Falcon you will probably want to use a

decent, fast 3.5" drive so you can

buy an adaptor. These are generic so a good

computer shop may have one, although they

are not that common. Wizztronics sell them

but you should be able to find other sources

of them. I believe they are also used on

Amigas.

If you are

attempting this on a normal Falcon without

a CT60 then you will need a new power switch.

You'll need to change the power switch from

the momentary type supplied to a latching

one. If you look through electronics catalogues

you'll probably find something very similar

to the one in your case but of a latching

type. Use the wires off the old switch and

solder them to the new switch. Keep the

old switch if you're intending on using

a CT60 as you'll need to fit that momentary

switch back in place.

All the front

panel switches and LEDs have small plugs

to fit headers mounted on the board. I used

a single row header to mate with these plugs

so they could be disconnected easily without

having to unsolder. At the moment the CT60

is still in development but it will come

with an ATX power supply connector so it'll

be a "plug-and-play" affair. The

CT60 will also support the PSU's full features

like automatic shutdown. However, with a

normal Falcon, work has to be done to accept

this newer PSU.

Find the

grey wire coming out of the PSU (may be

labelled as PS-ON on the PSU's enclosure)

and a black ground wire to connect to the

power switch header. Polarity isn't a concern.

This will now turn the PSU on. Check by

plugging in the PSU and connecting an old

hard drive or fan up to the power connector.

It'll be a good idea not to cut off the ATX connector

if you intend to use a CT60.

The power

LED is quite simple and requires taking

one of the 5V wires (red) and putting a

100 ohm resistor in series with the LED

and then taking this to ground. LEDs only

work one way around but it won't destroy

it having it around the wrong way so play

around before finalising the soldering.

|

This is how to

connect up the new PSU to the

Falcon connector. Please check

the voltages in case your PSU

doesn't follow the standard

for these power supplies. |

To use the

reset switch on the front of the tower case

you need to get the reset header and connect

the two reset wires across the capacitor

near the 3.6720MHz oscillator. It's a large

axial type. Polarity of the reset wires

is also not a concern.

|

These points on

the Falcon hook up to the tower's

reset switch. |

This is a

freeware schematic I used to construct my

multi-scan adaptor. When the Falcon is connected

to a multi-scan monitor that is capable

of a horizontal sync. down to 15KHz the

switch can be used to select VGA or RGB

mode. Warning: trying to run in RGB mode

on an old VGA monitor may cause permanent

damage to it if it is not designed to work

at 15KHz. This switch can be switched in

the middle of a session without having to

do a reset, which is particularly useful.

The change takes place when a program is

run that checks the type of monitor attached

like most demos and games do. Use shielded

wires to stop ghosting and any other forms

of noise and distortion on the screen.

|

A freeware adaptor

for selecting between RGB and

VGA for multi-scan displays.

[Click

to enlarge] |

SCSI is quite

difficult if you wish to have an internal

bus as well as external. I used an internal

style 50-pin Micro D, IDC connector to connect

to the Falcon's SCSI 2 port. This is crimp-on

which uses very fine ribbon cable with a

pitch of 0.025 inch, the same as SCSI 3.

You then need to solder on internal SCSI

cable. I used 50-way with 5 headers. This

went around the front for the drive bays

then back to the back panel where I soldered

it onto a SCSI Micro D port, just like the

one on the back of the Falcon. This was

simply a case of wiring pin 1:1, 2:2 and

so on up to 50:50. You may wish to use other

plugs inside your Falcon as newer drives

commonly come with SCSI 3 connector. Look

at Connect World (http://www.connectworld.com) for pin-outs for

all the SCSI connectors. Just match up the

names when wiring up. The pin numbers for

the connectors should be given on the connector

itself, you may need a magnifying glass

on those Micro D connectors! Avoid SCSI

differential drives (LVD: Low Voltage Differential)

altogether for the Falcon.

The keyboard

was the original keyboard but I extended

the lead and placed a mini DIN 8-way plug

on the back of the tower. I used a spare

ST case and carefully cut off the back to

make it smaller. The Falcon's keyboard was

put in there as it had Keyclicks which isn't

too bad a feel compared to the spongey ST.

I would recommend hooking up a Mega ST keyboard

though as these have a better feel and it

took a lot of time to cut up the case. There

are free schematics on how to do this, or

you can buy an adaptor for a PC keyboard

and mouse called Qwertyx from Mario Becroft.

|

My Falcon keyboard

sitting in half an ST case. |

The light

for the hard drive on the front of the tower

case can be connected straight up to the

keyboard connector. I recommend soldering

two wires to the underside of the board

where the connector pins come through. This

light will function just like the one found

on the keyboard.

|

Hooking up the

tower's hard disk activity LED

to the Falcon. |

To finish

it off I replaced the stock LEDs in the

case with super-bright blue LEDs. I then

made a custom Atari Fuji logo badge to fit

the 25mm square on the front of the case.

I got a logo and resized it in Imagecopy

then printed it out and laminated it for

durability. I also built a special temperature

display that controls the fans inside the

case and fitted it into a spare drive bay.

I've got to use all those drive bays for

something, right?! I also added an external

pixel clock by following Jo Even Skarstein's

instructions.

Lastly I

made a LAN port to serial port convertor

because I had nothing that used the LAN

port. I can now leave my modem connected

to the Falcon and also have a null modem

cable connection to my PC for file transfer.

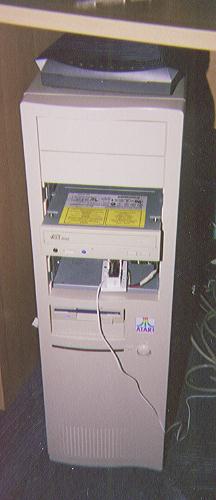

|

At this stage it

was almost completed, just finishing

the temperature display. |

|

Ahh,

as you can see the fans are

doing their job. |

|

Here are the ports

lined up on the back panel.

The PSU's connectors were extended

to a panel made of 1mm thick

steel bolted in where the PSU

would normally sit. |

|

The finished product. |

Overall it

is a modification worth doing if you wish

to have more space and a decent PSU that

can cope with lots of hardware extensions.

Just can't wait to slot in the CT60!

|

![]()

![[ Advert ]](images/banner.gif)

![]()

![]()

![]()

![]()

![]()

![]()